Share

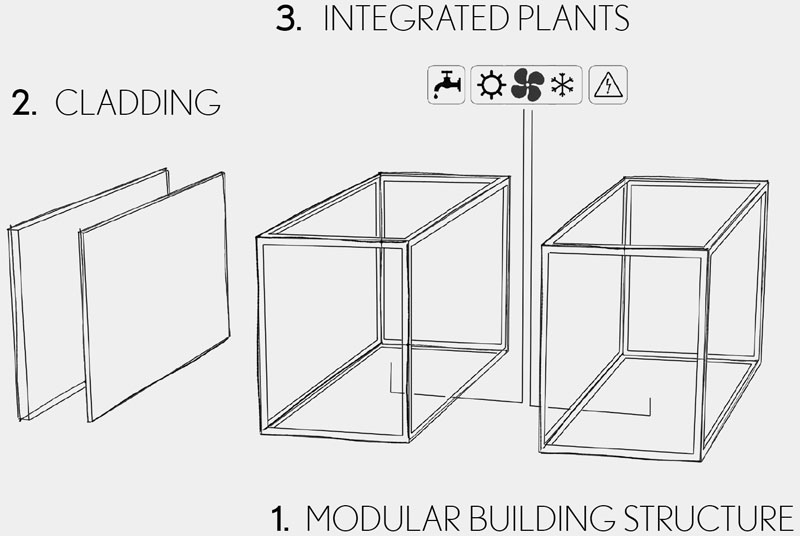

How it works

02

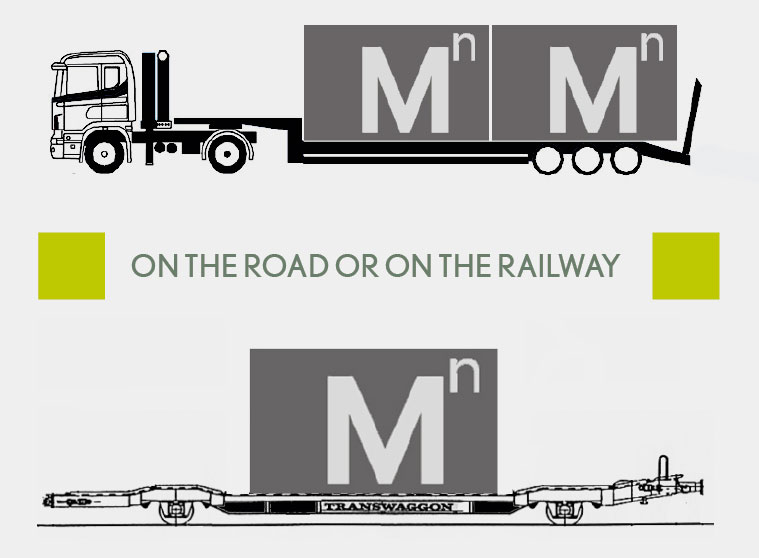

Fully transportable

The main advantage of this architectural system consist in the possibility to rapidly develop the project and assemble the single modules of the building in the construction, through a accurate quality control, till a final pre-testing. The modules are then transported by road to the destination where they are assembled together on steel foundation.

This construction method allows the realization of the building in a short time with great economic benefits, while minimizing accidents and ensuring a low cost and long-term maintenance.

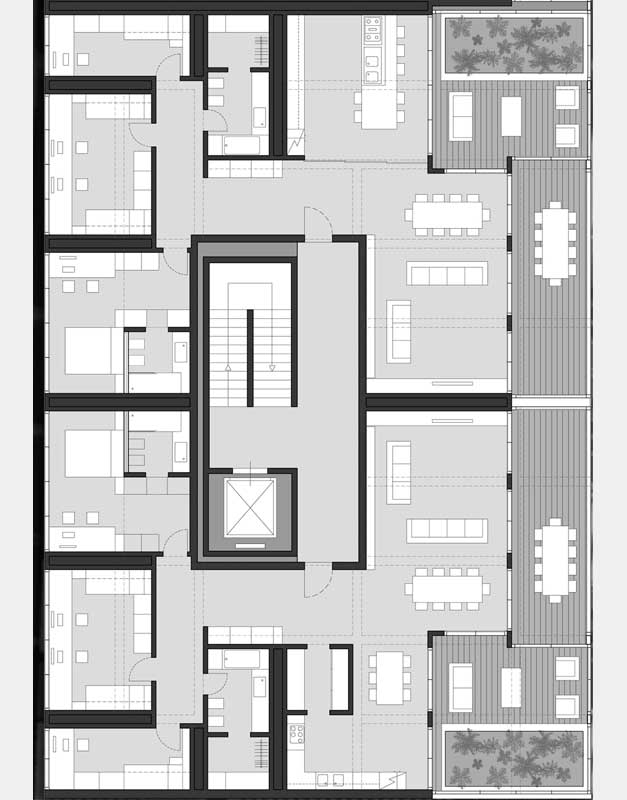

Social Interaction

A UNITARITY ARCHITECTURAL CONCEPT BASED ON QUALITY TO FAVOR THE RELATIONSHIPS BETWEEN PEOPLE AND BETWEEN PEOPLE AND NATURE

03

TECNOLOGY & DESIGN

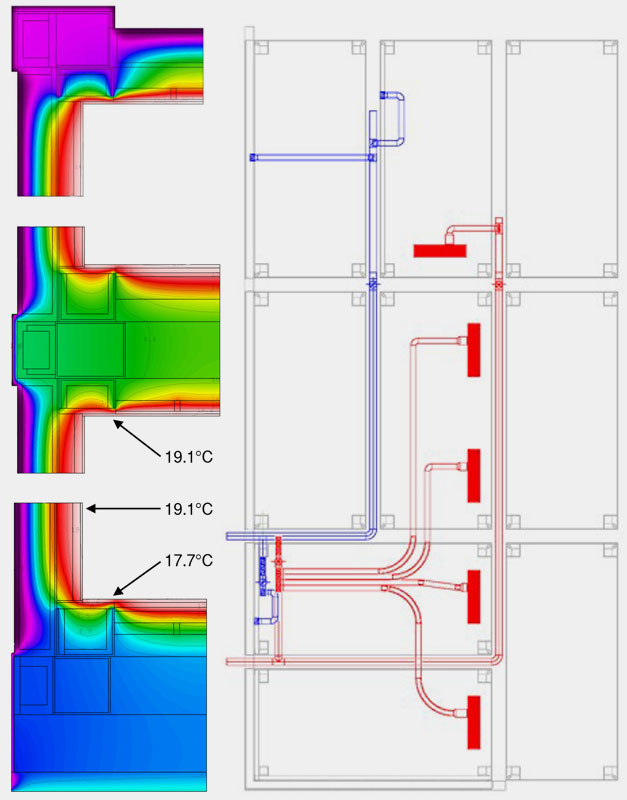

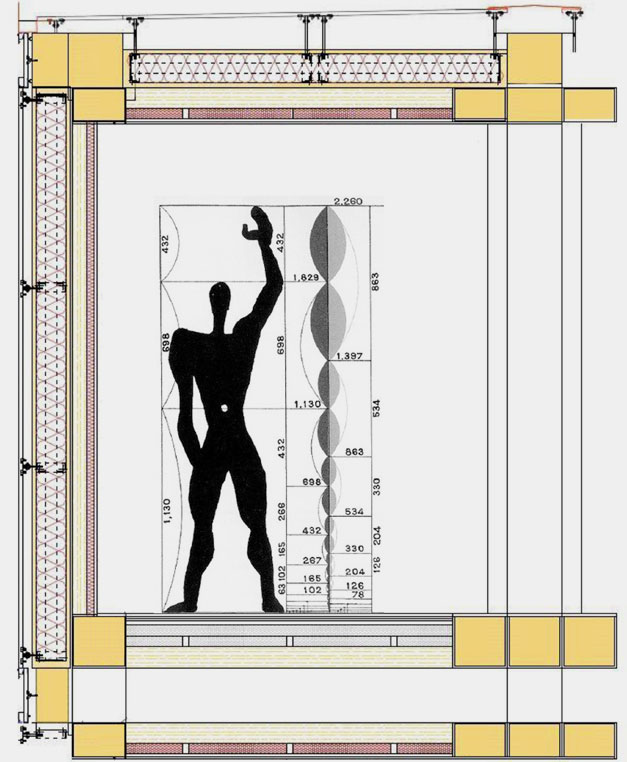

The module attachment joints have been designed to completely eliminate the structural thermal bridges. Steel joints and assemblyng devices are designed with suitable insulation to avoid points where critical temperatures can cause surface condensation. In fact, at each internal point, the internal temperature of the elements is higher than 17.7 ° C. This feature is extremely important because a high average radiant temperature due to the correct insulation ensures full comfort with thermostat temperatures set at 18 ° C In this way, energy consumption will be reduced by a further 25%. Below is the behavior of a traditional compartment with a thermostat temperature of 22 ° C The systems have been designed with the provision in the secondary backbone modules and for a quick assembly of the primary backbones and joints when assembling the entire structure. In this way the installation times of the same are considerably reduced, while ensuring high functionality. All units will be equipped with photovoltaic and solar thermal systems. The units will all be certified in class NZEB A4 according to the standards in force for new buildings as of 2019 as required by the European Directives on energy containment.

04